Discover how system simulation with Simcenter Amesim empowers your team to understand and optimize new design concepts at any point in your design cycle.

Discover how system simulation with Simcenter Amesim empowers your team to understand and optimize new design concepts at any point in your design cycle.

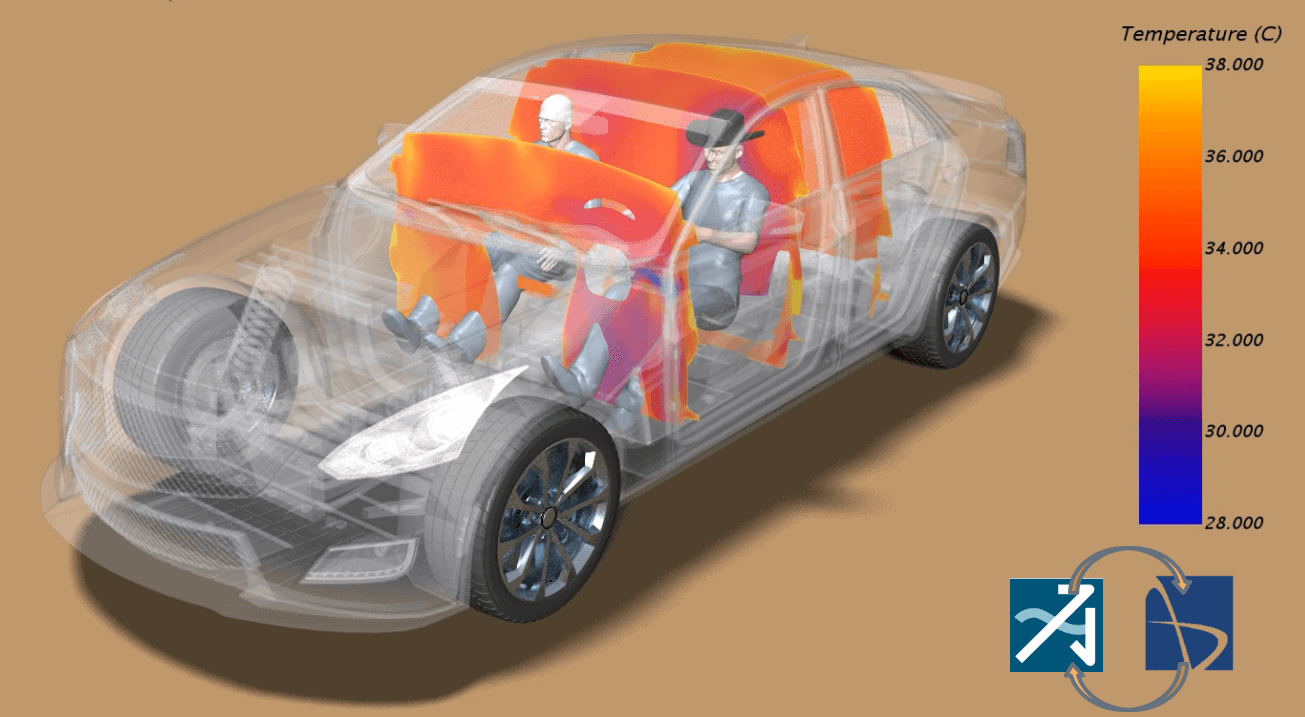

Whether you are modeling dehumidification systems for greenhouses, duty cycles for grocery store coolers, or full-vehicle cabin environmental control systems, optimizing the designs of environmental conditioning equipment involves multiple technical areas. These include refrigeration cycles, heating, humidity control, phase change, heat exchangers, electric power, controls, and more, all interacting within an environment that can change dynamically by the minute, hour, day, month, or season of the year. Model-based systems engineering (MBSE) enables the modeling of all necessary components and their interactions to predict and optimize performance for a given set of duty cycles.

Whether you are modeling dehumidification systems for greenhouses, duty cycles for grocery store coolers, or full-vehicle cabin environmental control systems, optimizing the designs of environmental conditioning equipment involves multiple technical areas. These include refrigeration cycles, heating, humidity control, phase change, heat exchangers, electric power, controls, and more, all interacting within an environment that can change dynamically by the minute, hour, day, month, or season of the year. Model-based systems engineering (MBSE) enables the modeling of all necessary components and their interactions to predict and optimize performance for a given set of duty cycles.

This on-demand webinar will describe the use of Siemens Simcenter Amesim for MBSE modeling of all kinds of environmental control systems, allowing users to optimize designs even at very early conceptual design stages.

In this webinar, we will discuss:

- Seeing the big picture: What is system modeling and why does it matter?

- Understanding where system modeling belongs in the development cycle

- Employing multiple levels of fidelity simultaneously

- Integrating subsystem models to handle even very large and complex systems

- Evaluating performance over a defined duty cycle or set of duty cycles

- Extending 1D models in Amesim with reduced-order modeling or co-simulation with more detailed engineering models, such as computational fluid dynamics (CFD) in Simcenter STAR-CCM+