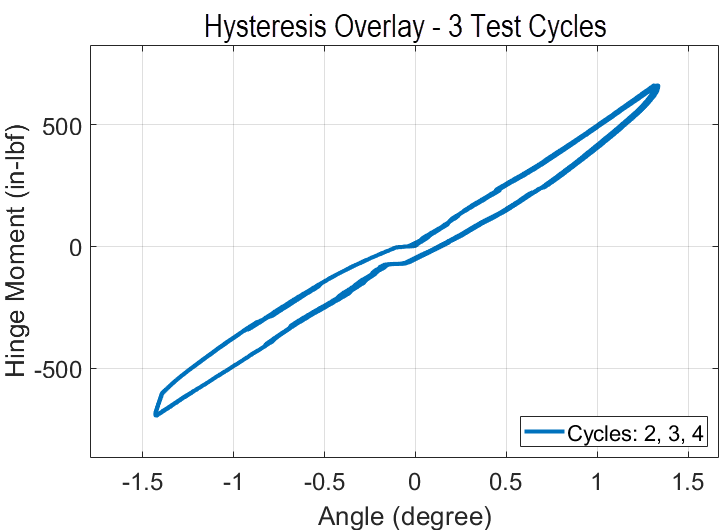

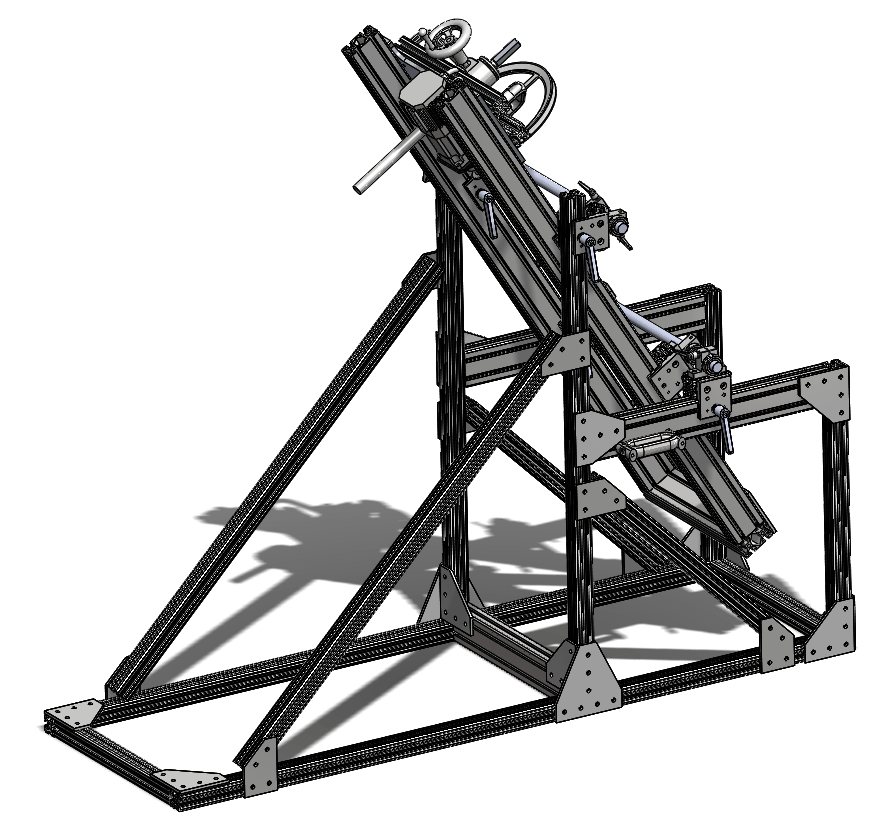

ATA performs free-play testing for our customers to evaluate rotational variation in aircraft control surfaces. Excessive control surface free-play can result in flutter, vibration, fatigue, or other instabilities that affect aircraft performance and safety. ATA has developed free-play testing procedures that provide highly repeatable and precise test results with minimal aircraft downtime to optimize cost and operational efficiency. With over a decade of experience conducting free-play testing across a spectrum of aerospace systems, including large military aircraft and small commercial planes as well as intricate satellite hinges, ATA engineers possess the expertise needed to deliver exceptional results for all aspects of free-play testing in aerospace, from the design and fabrication of free-play test fixtures that apply loads or hold displacement measurement transducers at the correct position to test planning, test execution, data postprocessing, and reporting.

ATA’s free-play test team has been praised by customers for producing some of the highest-quality free-play test data, earning recognition for consistently meeting demanding deadlines without sacrificing data integrity. The highly efficient free-play test procedures and real-time data processing at ATA accelerate test schedules and reduce aircraft downtime for our clients. Initial test results are available to the customers within minutes of test conclusion, allowing for immediate confirmation of data quality. ATA’s expertise in designing and adapting test fixtures around aircraft ensures that all test requirements are satisfied without sacrificing data quality or test scheduling. Additionally, the highly experienced staff at ATA provide comprehensive test and analysis services, bringing extensive troubleshooting experience to the process to reduce risk, cost, and schedule.

FEATURED Brochure

Free-Play Testing

Connect with us to discuss how our advanced multi-disciplinary team can help you achieve your engineering goals.