- Be robust enough to withstand the static and dynamic loading due to launch and ground handling

- Function after exposure to extreme temperatures

- Meet optical requirements in the presence of any dynamic, static, or thermal operating loads by minimizing distortions and relative displacements

- Be designed such that its requirements for prelaunch adjustment, calibration, and testing can be met in the context of the larger system

- Be lightweight enough to meet mass requirements

To achieve these objectives, an instrument’s design progresses through various phases that involve both analysis and test. ATA is experienced in working as a tightly integrated multidisciplinary engineering team to provide analysis and test services for ground, air, and space-based opto-mechanical systems throughout the entire design cycle to validate that the instrument design can meet its intended functionality under the operational and survival environments. This support includes initial definition of dynamic and thermal environments, analysis-driven design to optimize both structural and optical performance, and testing to correlate analytic models and qualify subsystems for their operational/qualification environments. ATA’s multidisciplinary optical performance modeling capabilities include Structural, Thermal Optical Performance (STOP) analysis, coupled optics and structural dynamics modeling, and prediction of distortion, jitter, wave-front error, pointing error, and stability.

ATA can support the design of opto-mechanical systems in various capacities, including structural design optimization, multidisciplinary optical performance modeling, and test verification planning and support. Typical areas where we support customers include the following.

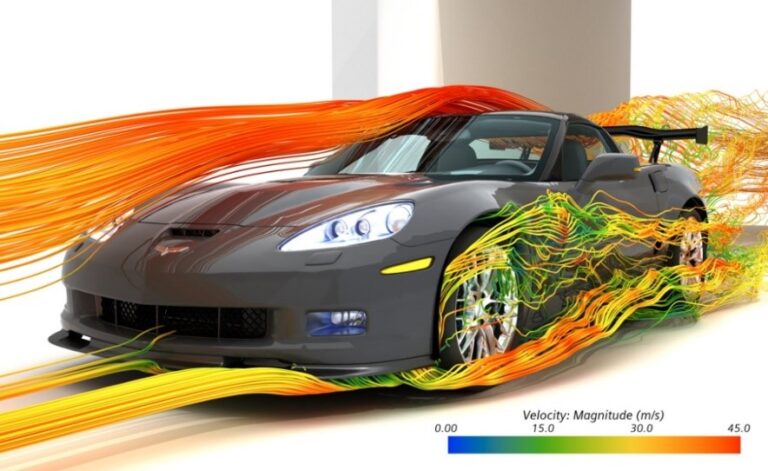

- Definition of design loads and environments for quasi-static, thermal, and dynamics (e.g., launch dynamics/acoustics, wind, seismic, and operational).

- Conceptual and detailed structural design and analysis of mechanical interfaces and subsystem and system-level structures

- Metallic and tailored-composite structural design to minimize weight

- Structural optimization to meet optical performance requirements

- Design of isolation to mitigate vibration and maximize optical performance

Independent design assessment

- Development of coupled optics, thermal, and dynamic models and application by a tightly integrated multidisciplinary engineering design team

- Use of coupled models to predict distortion, jitter, wavefront error, pointing error, and stability under operational dynamic and thermal environments

- Use of geometric optics approximations to assess system performance when aberrations are large compared to optics wavelength

- Defining environmental test requirements

- Pretest analysis

- Test planning, preparation, and instrumentation

- Ground vibration and modal testing

- Qualification and acceptance testing

- Posttest model correlation and verification

- Estimation of optical performance from dynamics test data

ATA has contributed various levels of design, analysis, and testing for large and small ground, air, and space-based optical or optical support systems, including the James Webb Space Telescope, Space Interferometry Mission (SIM), Stratospheric Observatory for Infrared Astronomy Program (SOFIA), NuSTAR telescope, Mars Science Laboratory, the Airborne Laser system (ABL), and a large ground-based radio telescope. This project experience includes work on a diverse range of optical systems such as telescopes, electron beam lithography machines, interferometers, airborne and ground-based laser systems, cameras, and sensor/detectors. Many of these programs have had very challenging requirements for maintaining sensor alignment and minimizing distortion and jitter under a variety of static, dynamic, and thermal environments. ATA is well versed in meeting structural optimization requirements of optical systems to minimize weight while ensuring overall structural integrity and optical performance. To maximize program value, ATA provides a multidisciplinary engineering team (thermal, mechanical, optical, test) that works together in a tightly integrated and collaborative fashion, accelerating the design process into production on time and within budget.

FEATURED Technical Paper

Designing, Tuning and Testing the Dynamics of Segmented Mirror Telescopes for Optical Performance

Connect with us to discuss how our advanced multi-disciplinary team can help you achieve your engineering goals.