Materials characterization focuses on measuring, calculating, or quantifying pertinent physical, thermomechanical, chemical, optical, and/or electrical properties of materials, to provide a better understanding of material responses at multiple length scales and to predict the material’s performance in its intended application. These efforts to understand process–structure–property relationships for highly engineered materials, such as the high-temperature composites used in hypersonic and reentry vehicle thermal protection systems, are often driven by costly and lengthy empirical testing programs. ATA has led innovations in applying physics-based simulations, machine learning algorithms, and computational chemistry to generate predictive digital engineering models that reduce reliance on empirical testing and deliver rapid, cost-effective insights that drive more affordable capacity for material manufacturers and their customers.

For the past decade, ATA has been an industry leader in characterizing materials and developing process and performance models of novel highly engineered composites, such as carbon-carbon and ceramic matrix composites (CMCs), which are used in extreme high-temperature environments. ATA has developed our COMPAS material characterization software framework under the sponsorship of NASA and several Department of Defense agencies and repeatedly deployed it to support manufacturers and their customers in linking processing methods with material performance, quantifying material model parameters using limited test data, and simulating linear and nonlinear aerothermomechanical and ablative material responses. These technologies have been critical to our customers, supporting material screening early in the design process and driving model-informed decisions on material selection and design integration by providing insight into material responses and uncertainties associated with the material’s damage and failure modes before component manufacturing begins. ATA’s material characterization capabilities have enabled our partners to make technological breakthroughs in material processing that accelerated the time to market for new materials, reduced the amount of scrap material, and increased the consistency and reliability of their material solutions.

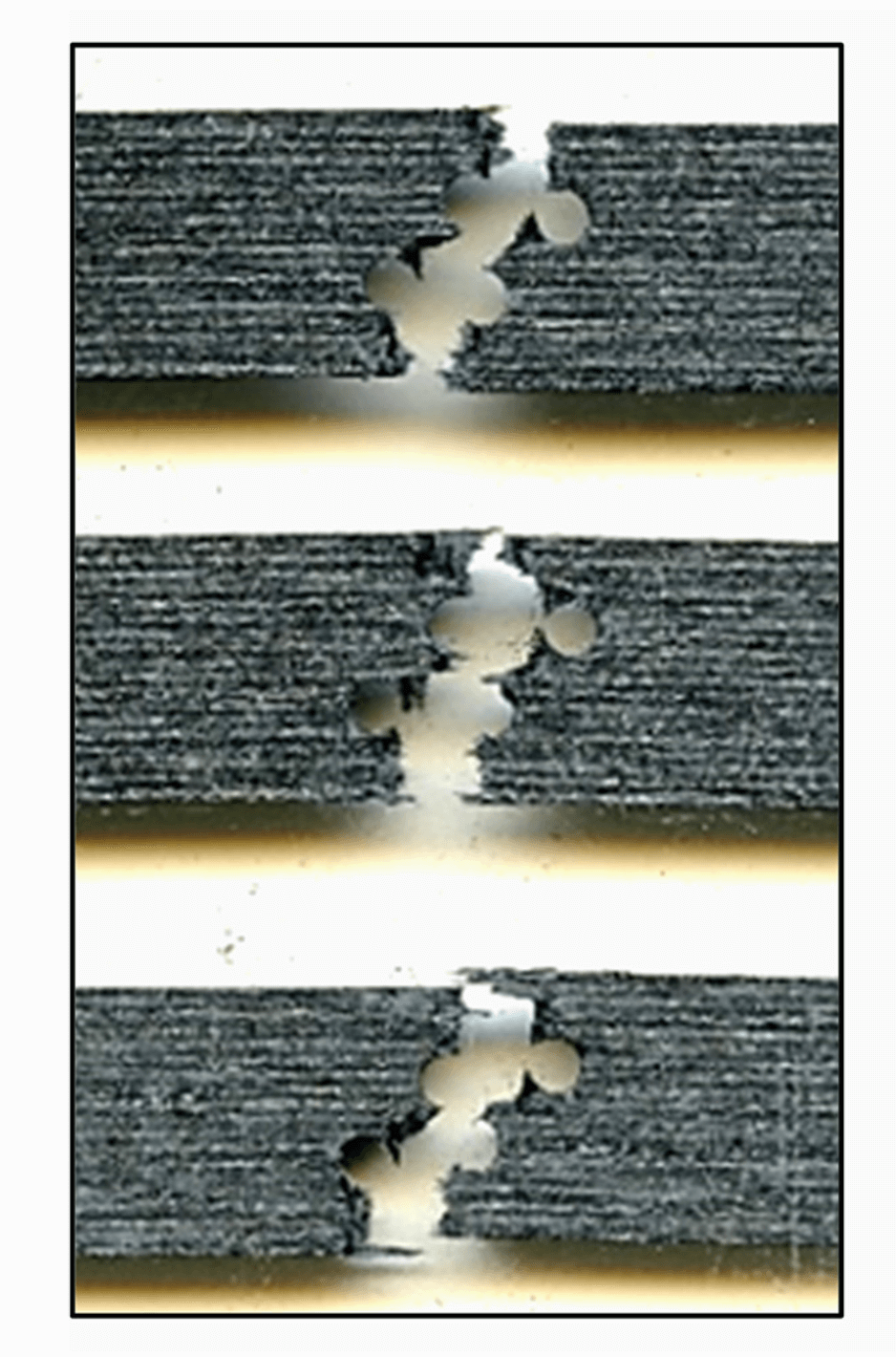

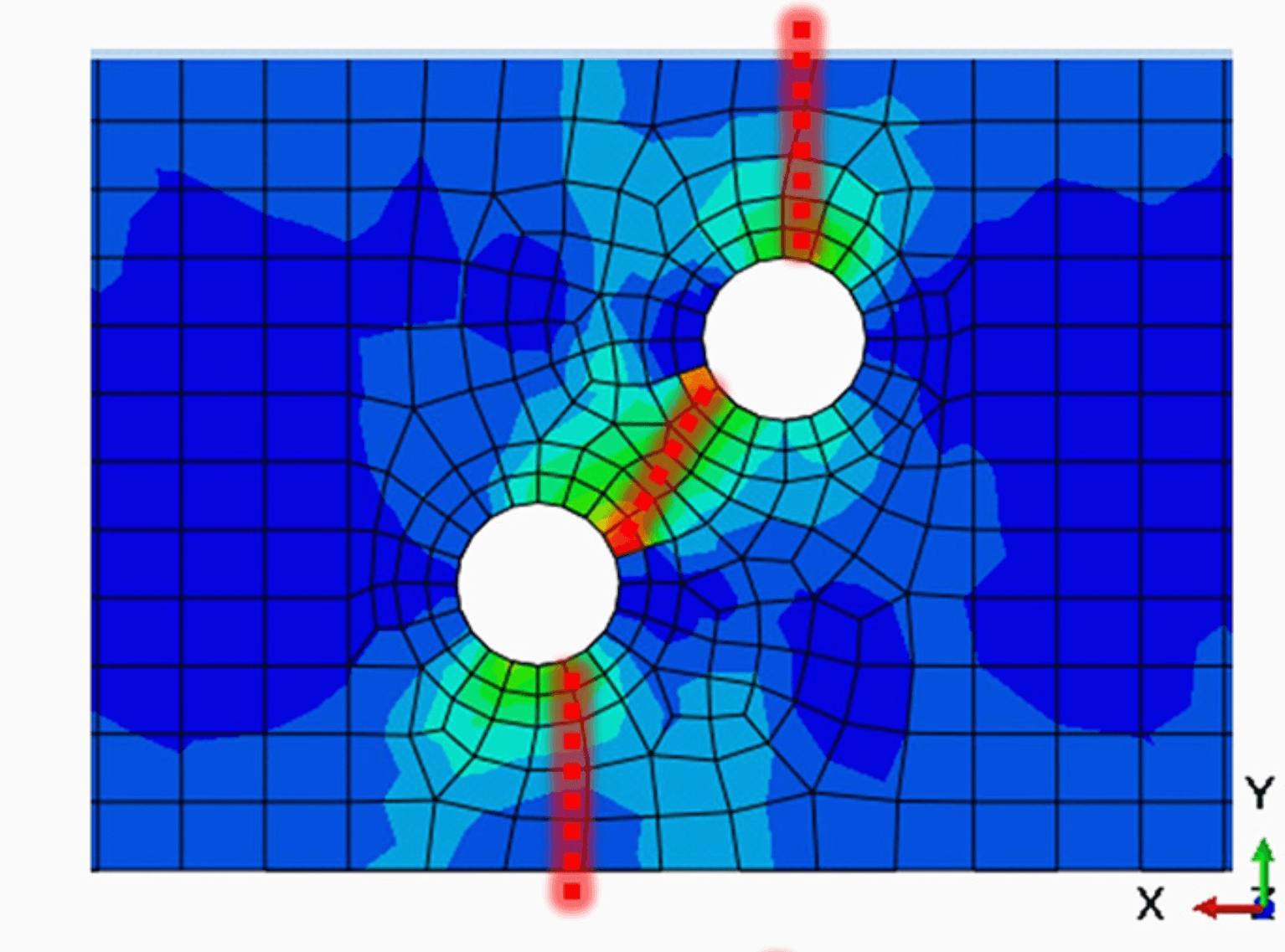

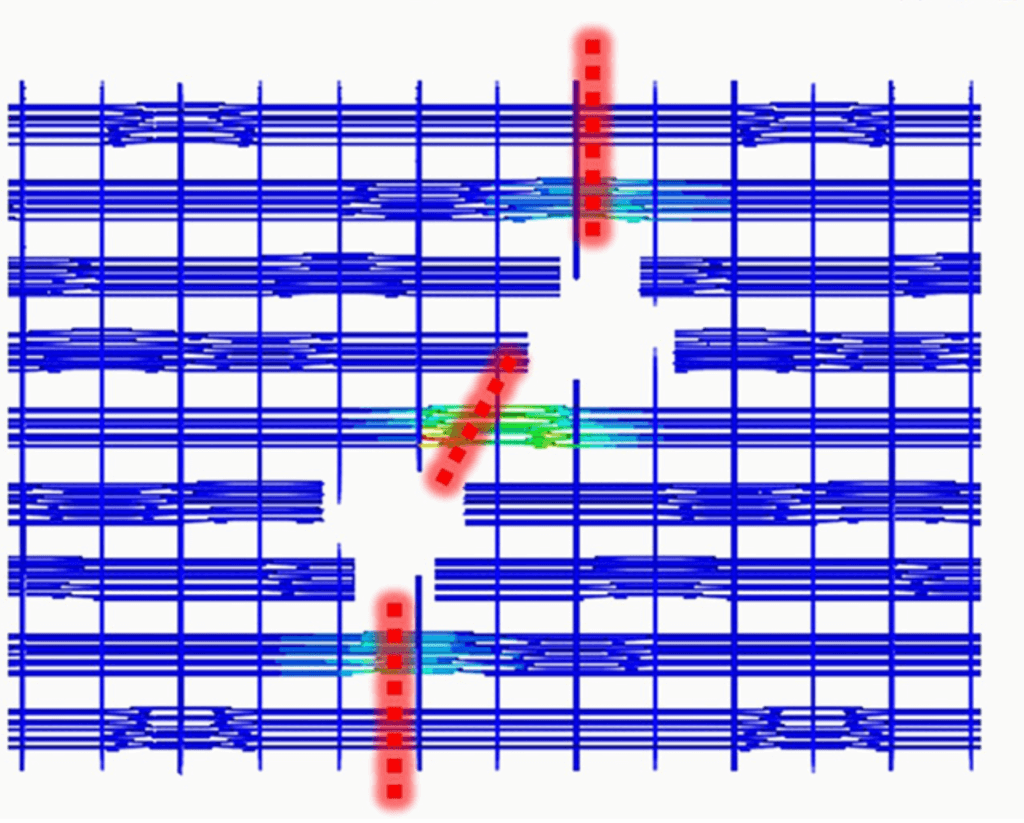

Predicted and actual failure paths for a ceramic matrix composite component using a COMPAS-calibrated material model.

*Selected Graphics: Gokce, A., R. Menefee, and L. Brown Simulation of CMC Mechanical Response Under Monotonic, Creep, and Fatigue Loading. International Journal for Multiscale Computational Engineering 19, No. 6, 2021.

Connect with us to discuss how our advanced multi-disciplinary team can help you achieve your engineering goals.