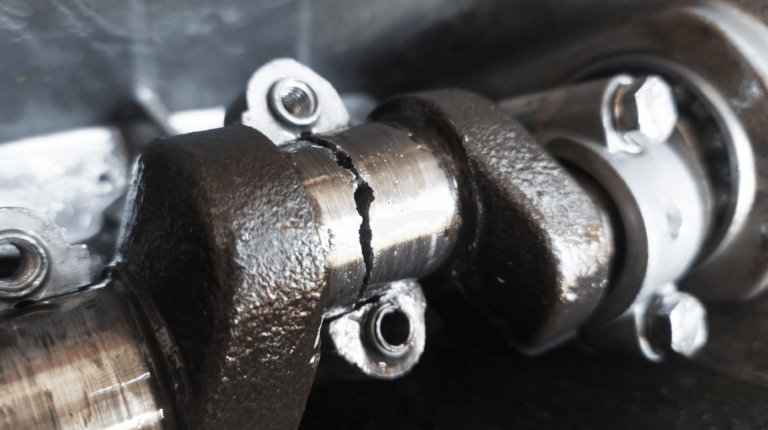

When a structure is subjected to cyclic loads due to dynamic motion or repetitive static loading, fatigue and damage tolerance are a concern. Fatigue analysis focuses on the initiation of a crack in a nominally flawless part, whereas damage tolerance analysis investigates the propagation of an existing flaw through a part. ATA has experience performing fatigue and damage tolerance (also known as fracture) analysis to address these concerns for multiple industries: themed entertainment rides, show action equipment, and animatronic figures; industrial equipment for load mechanisms in mining; and aerospace structures including fixed-wing aircraft, launch vehicles, spacecraft, and satellites; and more.

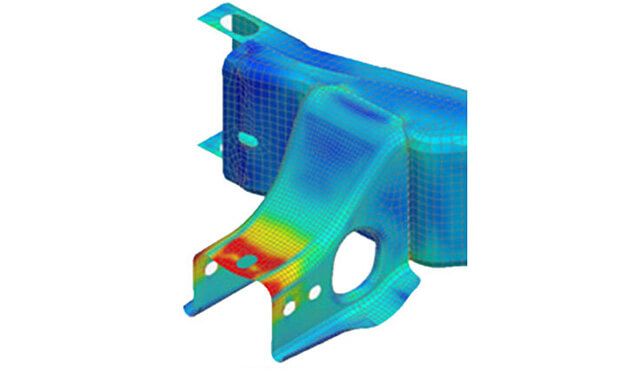

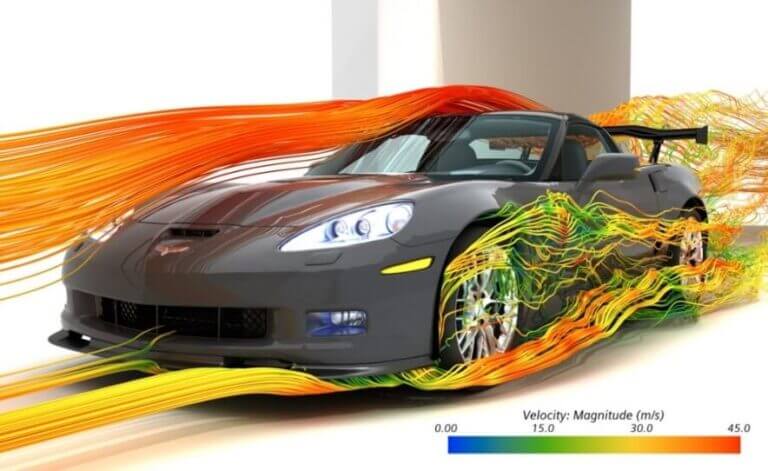

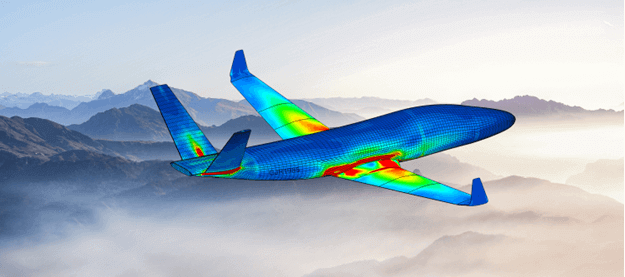

ATA engineers typically evaluate the fatigue life of parts made from metals and composites by using computer-aided engineering (CAE) tools like Siemens Simcenter 3D to determine stresses and strains throughout the duration of a part’s duty cycle. The duty cycle is generally composed of stress or strain data from various events, and the event data may be gathered from test measurements or from finite element analysis (FEA) evaluation of various environments, including static, quasi-static, dynamic modal response, multibody rigid response, and multibody flexible dynamic response. Next, cycle-counting methods like rainflow counting are used to deconstruct the stresses and strains and organize them into meaningful bins for fatigue analysis. The cycle-count bins, each representing a number of cycles at a particular stress mean and amplitude, are then evaluated for damage results depending on how they relate to the material’s fatigue S-N curve. When determining damage results, ATA engineers apply all relevant considerations, including mean stress effects, weld effects, biaxiality, temperature effects, surface effects, rate effects, scaling effects, endurance limits, and structural code requirements. The results are then combined to determine cumulative damage using methods like Miner’s rule. The final result is a prediction that can be used by designers, system engineers, or program managers to move ahead with confidence in the ability of a part to meet its structural fatigue requirements.

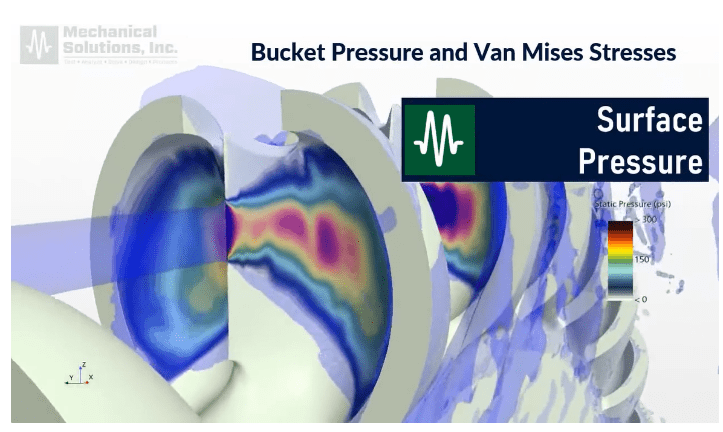

ATA engineers also use computer-aided tools to evaluate damage tolerance of parts made from metals and composites. In fact, the duty cycle is determined and separated into bins in the same way as in fatigue analysis; however, instead of evaluating the results against fatigue curves, the cycle-count bins are aggregated into a load spectrum and imported into the NASA-approved fracture analysis software tool NASGRO. Along with input of the load spectrum, we will also choose the most representative model from the NASGRO predefined crack-growth models. The distribution of stress on the NASGRO model will be determined with consideration of the stress field output from the structural solver (e.g., Simcenter 3D) or from test data and may employ combinations of axial, bending, and torsion stresses and univariate stress distribution, bivariate stress distribution, and stress intensity factor (SIF) compounding. The material model used in a damage tolerance analysis is critical and can be complicated. Fortunately, NASGRO comes with an extensive library of material models, and ATA engineers are expert at understanding and manipulating those models to achieve project-specific requirements. Once the model, load, stress, and materials are input, NASGRO produces results that indicate whether a flaw will not grow at all, grow within acceptable levels, or grow to unacceptable levels. Often, multiple parameters—such as the crack model, crack size, and loading order—are varied in a fracture analysis to identify the sensitivity of potential conclusions to assumptions made in the analysis. ATA engineers then use the aggregation of these results to provide a conclusion that can be used by designers, system engineers, or program managers to move ahead with confidence in the ability of a flawed part to meet its duty cycle requirements.

ATA also performs nonlinear crack growth analysis when necessary—particularly for very ductile metals. For composites and other nonmetallics, damage tolerance and crack growth must in most cases be evaluated empirically, and ATA is proficient in test planning and oversight for such evaluations.

Standards Experience

ATA staff have expertise in the application and interpretation of fatigue and fracture requirements for metallic welded, unwelded, and bolted structures subjected to cyclic loading. The following are some of the fatigue standards that ATA has extensive experience in applying:

- American Institute of Steel Construction (AISC) 360 Steel Construction Design Manual

- Aluminum Association (AA) Aluminum Design Manual

- American Welding Society (AWS) D1.1 and D1.3

- International Institute of Welding (IIW) Recommendations for Fatigue Design of Welded Joints and Components

- British Standard (BS) 7608

- Deutsches Institut für Normung (DIN) 15018-1, -2, and -3

- Det Norske Veritas DNV-RP-C203 Fatigue Design of Offshore Steel Structures

- European Committee for Standardization (CEN) EN 1993-1-9 Eurocode 3: Design of steel structure

- Forschungskuratorium Maschinenbau (FKM) Guideline: Analytical Strength Assessment of Components Made of Steel, Cast Iron, and Aluminum Materials in Mechanical Engineering

- Standardization Administration of China (SAC) GB 50017 Code for Design of Steel Structures (China)

- NASA-STD-5019A Fracture Control Requirements for Spaceflight Hardware

FEATURED Case Studies

Dynamic Stress Analysis of THAAD Seeker IGA

The Theater High Altitude Area Defense (THAAD) missile system is a transportable defensive weapon that uses precision targeting to protect against hostile incoming threats such as tactical and theater ballistic missiles. BAE Systems (BAE) is responsible for providing the infrared (IR) seeker subsystem, stabilized on a two-axis integrated gimbal assembly (IGA), which is subjected to . . .

FEATURED Case Studies

Fatigue-Life Assessment on a Seismic Source Vehicle

Inova Geophysical manufactures the UNIVIB™ (PLS-326) small vibrator vehicle used for vibroseismic operations during oil and gas exploration. ATA provided operational test services for three variations of the UNIVIB vehicle.

Connect with us to discuss how our advanced multi-disciplinary team can help you achieve your engineering goals.