Over the past decade of delivering engineering methods development solutions to our customers, ATA Engineering’s multidisciplinary expertise in traditional engineering fields and innovations in AI/ML algorithms have provided unique value in delivering rapid, trusted insights in the face of challenges once thought to be intractable due to computational costs for physics-based simulation or analysis of large volumes of empirical data.

While many organizations tout the transformative, all-encompassing possibilities of AI/ML technologies for the world of tomorrow, ATA’s approach to harnessing AI/ML focuses on delivering solutions today using tools and methods tailored to specific customer challenges.

When our customers struggle with bottlenecks in their engineering processes that hinder their cost and schedule performance or their ability to leverage advancements in modeling and simulation or experimental measurements, ATA takes a holistic, multidisciplinary approach to identifying innovative engineering methods. ATA engineers apply their wide-ranging expertise in physics-based modeling and simulation, data science, AI/ML algorithms, testing methods, and statistical analysis. Oftentimes these efforts involve leveraging academic research and implementing new technologies in customer program settings or as applied research solutions using rigorous phased development approaches and clearly defined verification and validation milestones to mitigate technical risks.

When developing custom AI/ML solutions to address specific engineering challenges, ATA focuses on providing our customers with insights into the utility and trustworthiness of models by leveraging advancements in uncertainty quantification, documenting the deployed algorithms, providing clear direction on the required investments in network training data, and defining the bounds of applicability for AI/ML models where they are able to provide high confidence in the rapid insights they deliver. This approach differs from many state-of-the-art commercial ML modeling tools that offer a “black box” user experience shrouded in proprietary algorithms and underlying training databases with potentially questionable relevance to the problem at hand.

Our ML Workflows and Tools

ATA has experience applying a wide variety of ML workflows and tools across engineering disciplines, including:

- Automated development of fast-running reduced-order surrogate models trained on nonlinear progressive damage simulations of high-temperature composite material coupon tests to enable statistical analysis and rapid inference of constituent material thermo-mechanical properties

- Multi-fidelity ML approaches that significantly reduce network training costs by combining large amounts of available low-fidelity simulation data with limited amounts of high-fidelity simulation data to deliver rapid predictions approaching high-fidelity accuracy for modeling the thermal history of additively manufactured metal parts based on part geometry, path definition, and process parameters

- Implementation of clustering algorithms and variational autoencoders to predict the microstructures of additively manufactured metal parts given a predicted or measured temperature history

- Incorporating physics constraints into neural networks and other ML algorithms to confine models to realistic solutions, thereby reducing training costs and improving network accuracy, for applications including the prediction of remaining usable life for lithium batteries

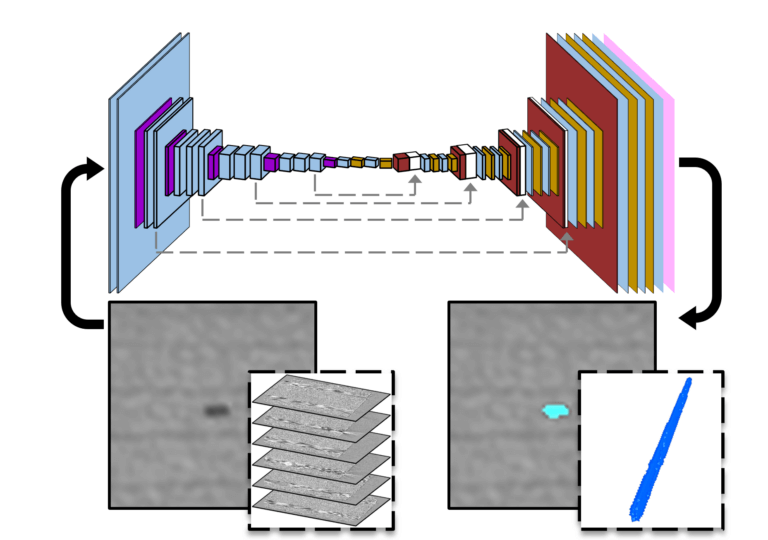

- ML tools for automated segmentation of computed tomography (CT) imagery to rapidly generate image-based models of composite components and predict how as-inspected defects will impact performance of manufactured parts

- Incorporation of uncertainty quantification by various methods, including the use of Bayesian neural networks

- Integration of ML reduced-order models into existing commercially available software, including finite element analysis tools

If your team is seeking more-rapid methods to derive engineering insights from simulations, in-situ diagnostic sensor data, and collected experimental measurements, contact ATA today to discuss your goals and objectives.

Connect with us to discuss how our advanced multi-disciplinary team can help you achieve your engineering goals.