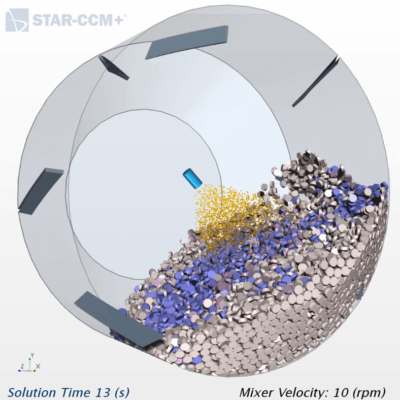

Discover a hidden gem of STAR-CCM+: its ability to combine a Discrete Element Method (DEM) solver for modeling particles with the CFD fluid solver.

Simcenter STAR-CCM+ delivers a comprehensive suite of Lagrangian Multiphase and DEM models for simulating the handling and processing of granular materials in various industrial equipment. This DEM modeling capability is fully integrated into the Simcenter STAR-CCM+ environment, enabling seamless DEM–CFD coupling to solve problems involving fluid and granular phases together.

Simcenter STAR-CCM+ delivers a comprehensive suite of Lagrangian Multiphase and DEM models for simulating the handling and processing of granular materials in various industrial equipment. This DEM modeling capability is fully integrated into the Simcenter STAR-CCM+ environment, enabling seamless DEM–CFD coupling to solve problems involving fluid and granular phases together.

DEM accurately resolves collisions between solid particles in dense granular flows, such as the solid bulk material flows that are part of many processes in the chemical processing, pharma, oil and gas, energy, construction and mining, and food industries. DEM provides accurate prediction of the solid particle flow, particle accumulation and blockage, segregation by particle size, and surface wear in solid material handling and processing equipment, and it is also able to predict energy consumption from running the process or machinery.

Applications include:

- DEM–CFD coupling without co-simulation

- Fluidized bed reactors

- Biomass fuel in gasifiers

- Packed bed reactors

- Fluidized bed coating

- Pneumatic conveyors

- Mixing and coating

- Solid bulk material handling

- Augers

- Conveyors

- Chute transfers

- Hoppers

Join Dr. Ravindra Aglave of Siemens Digital Industries Software and Adam Green of ATA Engineering, Inc. for a deeper dive into this topic.