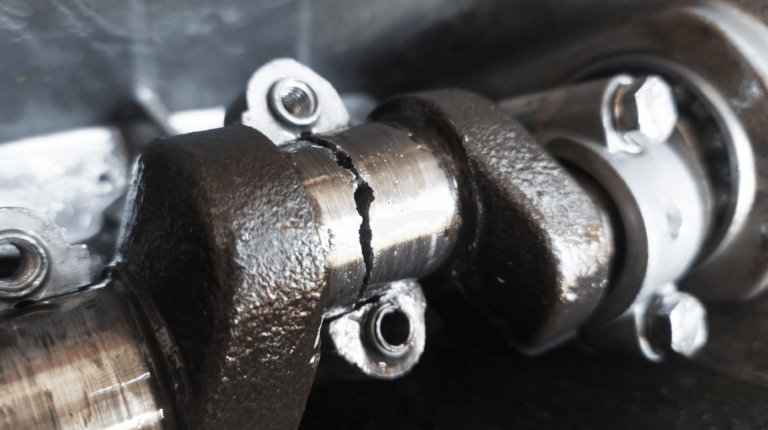

ATA Engineering has more than 45 years of experience in assessing and solving challenging structural design and operational issues for mining equipment and heavy industrial machinery in a wide variety of industries and for a diverse range of domestic and international customers. From measurement and analytical prediction of operational loads to complete system structural assessments and retrofits, ATA has provided valuable insight and design solutions to improve the operational performance and extend the life of mining and industrial equipment, such as steel roll mills, paper mills, crushing and ball mills, draglines, hoisting equipment, mine shaft equipment, conveyors, stackers, reclaimers, vibratory screens, seismic vehicles, recycling trommels, excavators, haul trucks, and more. Our profound understanding of dynamic loads, structural response analysis, and fatigue life assessment makes ATA an exceptional engineering consulting team to support heavy equipment manufacturers and end users.

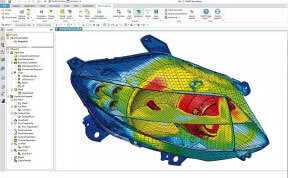

As an engineering services company focused on analysis- and test-driven design, ATA is uniquely positioned to respond with flexible, adaptive solutions and provide varying levels of support depending on client and project needs. We are industry leaders in the development and implementation of analysis and test methods that ensure that projects are carried out as efficiently as possible. Our staff members are experts in the use of a wide variety of CAD/CAE software packages, including NX, Simcenter Nastran, Abaqus, Ansys, and Femap. Our mechanical engineers are recognized experts in addressing durability and fatigue issues for welded structures, and our related work over the past 45+ years has become the basis for design standards utilized within the mining industry. We have a dedicated test team with more than fifteen test engineers, and we maintain test equipment that can record over 700 channels of acceleration simultaneously and condition over 200 channels of dynamic strain and displacement data. This test capability greatly reduces the number of runs required to gather relevant data and minimizes the impact on plant operation. Unique to ATA is our ability to correlate analysis and test results to provide a comprehensive understanding of the structural response and define robust, optimized solutions to resolve design or fatigue problems and to help expedite the process of getting equipment back into operation.

ATA’s relevant expertise in supporting the industrial and mining industries includes troubleshooting of equipment durability and vibration problems via analysis and testing, accurate load measurement during complex static and dynamic events, predictive maintenance assessment and comprehensive fatigue life estimation through explicit testing and/or finite element analysis, third-party review of equipment design and structural assessment, extended life analysis and development of practical/implementable design enhancements for aging industrial equipment, characterization of structural dynamic response and its transmissibility to neighboring equipment or operations, troubleshooting of rotating equipment (including identification of problem sources through sophisticated processing of vibration data), simulation of manufacturing processes such as rolling or forming, and nonlinear analysis to include the effects of material creep, surface contact, large displacements, or multibody dynamics.

FEATURED Brochure

ATA Engineering Capabilities Brochure

ATA Engineering, Inc., (ATA) is a 100% employee-owned mid-sized business that has been helping our clients solve their complex engineering problems in the areas of product design, structural dynamics, thermal analysis, aeroelasticity, acoustics, software development, computational fluid dynamics (CFD), structural mechanics, training, and testing since 2000

Connect with us to discuss how our advanced multi-disciplinary team can help you achieve your engineering goals.